A cleanroom wall panel is more than just a partition; it’s a highly engineered component specifically designed to meet the stringent requirements of controlled environments. These panels are typically constructed as sandwich structures, featuring a core material encased by two facing sheets. The primary role of a cleanroom wall is to create an impervious barrier that prevents the ingress of contaminants, such as particulate matter and microbial agents, from the outside environment into the controlled space. Furthermore, the cleanroom wall panel itself must be non-particle shedding and non-outgassing, meaning it should not contribute to contamination within the cleanroom. The surfaces are designed to be smooth, non-porous, and resistant to cleaning agents, facilitating regular and thorough sanitation.

The selection of the right wall panel is a cornerstone of effective cleanroom design. These panels integrate with other critical cleanroom systems, including ceiling systems, flooring, and HVAC, to create a holistic controlled environment. A well-designed panel system ensures airtight seals, minimizing air leakage and maintaining precise pressure differentials, which are crucial for preventing cross-contamination between areas of different cleanliness levels within a cleanroom. The overall cleanroom wall systems are fundamental to achieving and maintaining the desired ISO classification, directly impacting product quality and process reliability in sensitive industries like pharmaceutical and microelectronics. The integrity of the cleanroom wall contributes significantly to the operational efficiency of the entire cleanroom.

Beyond just forming a barrier, the cleanroom wall also plays a role in the overall structural integrity and functionality of the cleanroom. Modern wall panel systems can incorporate features such as integrated raceways for utilities, windows, and pass-through chambers, all while maintaining the necessary environmental controls. The choice of wall panel impacts not only contamination control but also factors like thermal insulation, acoustic properties, and fire resistance. Therefore, understanding the specific characteristics of different wall panel offerings is essential for building a cleanroom that performs optimally for its intended cleanroom application. A cleanroom’s success heavily relies on its structural components, like the cleanroom wall panels.

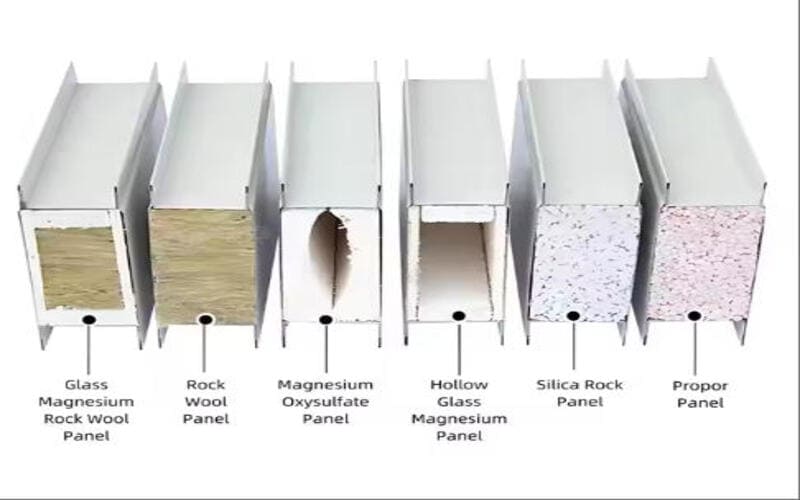

Our cleanroom sandwich panels are engineered to meet the stringent requirements of controlled environments. Utilizing advanced materials such as rock wool, polyurethane foam, polypropylene, magnesium oxysulfate, hollow glass magnesium, glass magnesium rock wool, aluminum honeycomb, and paper honeycomb, these panels offer unmatched insulation, fire resistance, and durability. Ideal for building cleanrooms, laboratories, and other sterile environments, our panels ensure safety and efficiency.

Our company provides comprehensive solutions for a variety of projects, including the construction of ISO cleanroom facilities, ensuring a seamless and efficient process from start to finish.

Sandwich panels feature a waterproof and fireproof design, providing maximum protection against moisture and fire, making them ideal for cleanroom projects where hygiene and safety are critical.

We offer customized color and thickness options to meet specific project requirements, including 50/75/100/120/150/200mm thicknesses and a wide range of colors to match your desired design style.

Our sandwich panels are designed for easy installation, and we provide on-site installation services to ensure a hassle-free experience for our customers

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Stay updated with industry news

Copyright © 2024 Bobencleanroom

Total Project Solutions