A Fan Filter Unit (FFU) is a type of motorized air filter equipment. At its core, an FFU consists of a fan, a motor, and a high-efficiency filter (typically a HEPA or ULPA filter) housed within a compact box or module. The primary function of this unit is to draw in ambient air from above, pass it through the filter, and then supply clean air into a controlled space below, such as a cleanroom. The motorized fan creates the necessary airflow, pushing air through the densely packed filter media. Many designs also incorporate a pre-filter to extend the life of the main filter by capturing larger particles.

The operational principle of an FFU is straightforward yet highly effective. Air is drawn into the unit from the plenum or the room itself, often through the top surface. This air first encounters the pre-filter, which removes larger dust and particle contaminants. The air then passes through the fan section and is forced through the main filter – commonly a HEPA filter capable of trapping 99.99% of particles as small as 0.3 micron, or an ULPA filter for even higher efficiency. The now highly filtered air is discharged at a controlled velocity downwards, often creating a laminar flow pattern that helps to sweep away any internally generated contaminants within the controlled environment. This continuous supply of clean air ensures that the desired cleanliness level is maintained within the designated area, typically mounted in a ceiling grid system. Each FFU operates independently, providing flexibility in design and scalability for various cleanroom sizes.

These fan filter units are designed for modularity, allowing them to be easily installed in standard ceiling grid systems. The self-contained nature of each FFU module means they don’t always require complex ducted air supply systems, although some applications might integrate them with a central air handler. This makes them a versatile solution for achieving and maintaining stringent air quality standards. The design of the fan filter unit aims to provide a consistent air flow with minimal turbulence, crucial for preventing cross-contamination.

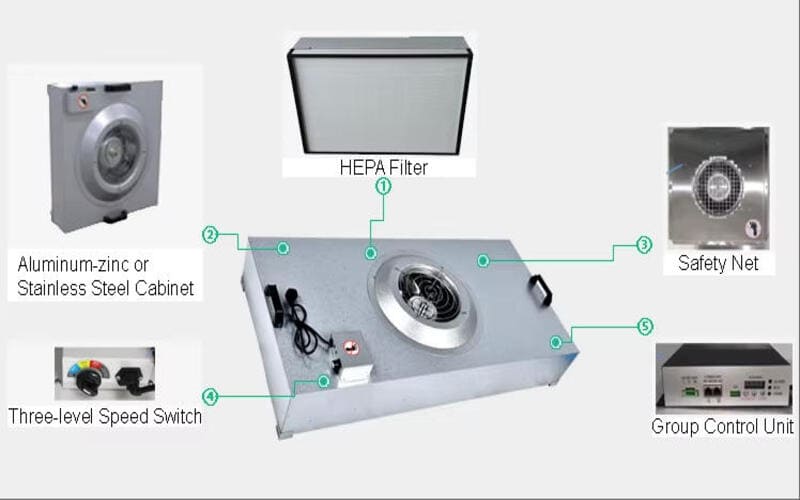

The fan filter unit is a self-powered terminal air supply device with a filtering function. The fan sucks air from the top and filters it through the HEPA filter to produce clean air and evenly deliver it from the air outlet. It provides stable and strict air environment control for the clean room. The fan filter unit can be connected in modules to meet the needs of different enterprises and scientific research for different clean environments.

Our FFUs have independent AC EC fans, providing highly efficient air purification, capable of capturing particles as small as 0.3um with a filtration efficiency of 99.995%. This ensures a clean and healthy environment in various industries.

The product is constructed of powder coated steel, making it a sturdy and long-lasting addition to any facility. Its compact dimensions (575x1175x300mm) allow for easy installation and minimal space requirements.

This FFU is suitable for various industries including manufacturing plants, food and beverage stores, electronics factories, air conditioning systems, chemical industry.

With a low noise level of 56 dB and fan vibration of 0.2~0.5mm/s, this unit provides quiet and stable operation. Its initial pressure drop is 220pa/0.45m/s, ensuring efficient airflow.

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Stay updated with industry news

Copyright © 2024 Bobencleanroom

Efficient air purification