A dispensing booth is a specialized piece of cleanroom equipment, often referred to as a local purification equipment or purifying equipment for materials sampling. Essentially, dispensing booth is also called a downflow booth, sampling booth, or weighing booth, and its primary function is to provide a controlled environment for handling powders and liquids, particularly during weighing and dispensing operations. These booths are designed to protect the operator, the product, and the surrounding cleanroom environment from contamination by airborne particles and dust. The dispensing booth creates a localized clean work area, minimizing the risk of cross-contamination and ensuring the integrity of sensitive materials, making it indispensable in the pharmaceutical industry, chemical processing, and biotechnology.

The necessity of a dispensing booth arises from the need for high levels of containment and cleanliness that might exceed the general cleanroom classification. While a cleanroom provides an overall controlled environment, operations like handling potent pharmaceutical ingredients or fine chemical powders can generate significant localized dust. A dispensing booth acts as a primary engineering control, capturing these particles at the source. This not only ensures a safe environment for the operator but also prevents the spread of these particles into the wider cleanroom, thereby safeguarding other processes and products from potential contamination. For precise tasks like sampling or weighing, the controlled conditions within a weighing booth or sampling booth are crucial.

Weighing Booth also know as laminar flow booth, dispensing booth is used for the microbiological research and scientific experiments and other places dedicated local purification equipment, which provides a ertical unidirectional airflow, some clean air circulation in the work area, partly discharged to the nearby area, so that the work area produce negative pressure to prevent cross contamination to ensure the high clean class level of the working area.

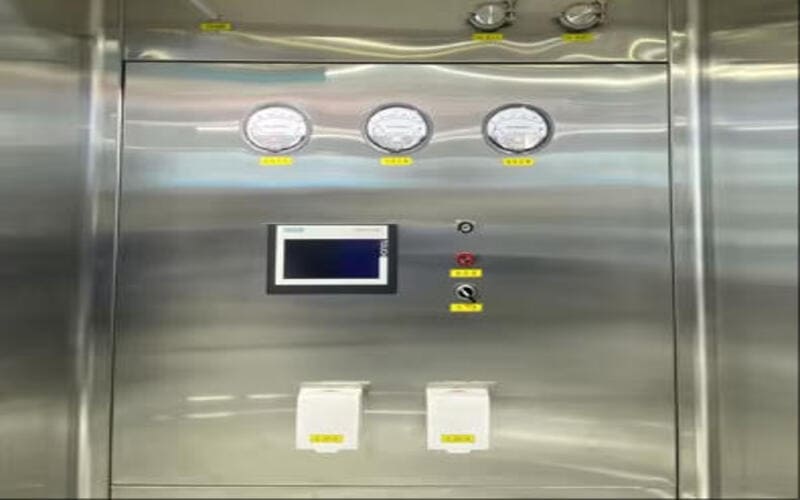

We use stainless steel to the whole part.

VFD Control (Variable Frequency Drive) /Simens PLC Control(Programmable Logic Controller)customized

Numbers of bacterial colony ≤0.5pcs/Petri dish.h(φ90㎜

HEPA efficiency(%@0.3 um) 99.99%

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Stay updated with industry news

Copyright © 2024 Bobencleanroom

All steel construction