A cleanroom air shower is a specialized, enclosed antechamber that personnel must pass through before entering clean zones, particularly a cleanroom. Its primary purpose is to remove loose particles and contaminants from individuals and their garments, acting as a crucial barrier against the introduction of unwanted particulate matter. Think of it as a high-tech vestibule, meticulously designed to scrub individuals clean using high-velocity streams of filtered air. This initial decontamination step is paramount because humans are often the largest source of contamination in a controlled environment, shedding skin cells, hair, and fibers from clothing.

The importance of the air shower as the first line of defense cannot be overstated. In industries where even a single microscopic particle can ruin a batch of sensitive microchips, compromise a sterile pharmaceutical product, or invalidate research data, preventing contamination at the entry point is critical. An air shower significantly reduces the bioburden and particulate load entering the cleanroom, thereby safeguarding the integrity of the processes within and helping maintain the required ISO classification (e.g., ISO 5 or Class 100). It’s a proactive measure, ensuring that the main cleanroom environment remains as pristine as possible. The air shower is a self-contained unit that plays a vital role in an overall contamination control strategy.

These systems are not just simple blow-off chambers; a modern air shower incorporates sophisticated filtration systems, often using HEPA (High-Efficiency Particulate Air) or ULPA (Ultra-Low Penetration Air) filters, and carefully engineered air nozzles to ensure effective cleaning. The cycle within an air shower is automated and timed, ensuring each person receives an adequate duration of air scrubbing. By intercepting contaminants before they reach the critical cleanroom environment, the cleanroom air shower helps reduce the load on the cleanroom’s own air handling systems, prolongs filter life, and ultimately contributes to higher product yields and operational efficiency.

The air in the air shower room is blown into the static pressure box by the fan. After being filtered by the filter, it is sprayed out from the nozzle at 360 degrees at high speed to blow off the dust attached to the surface of people or items they carry. The blown dust is recycled into the filter.

Stainless steel adjustable rotating nozzle.

Pure copper core motor, large air volume, low noise, air outlet speed up to 25m/s.

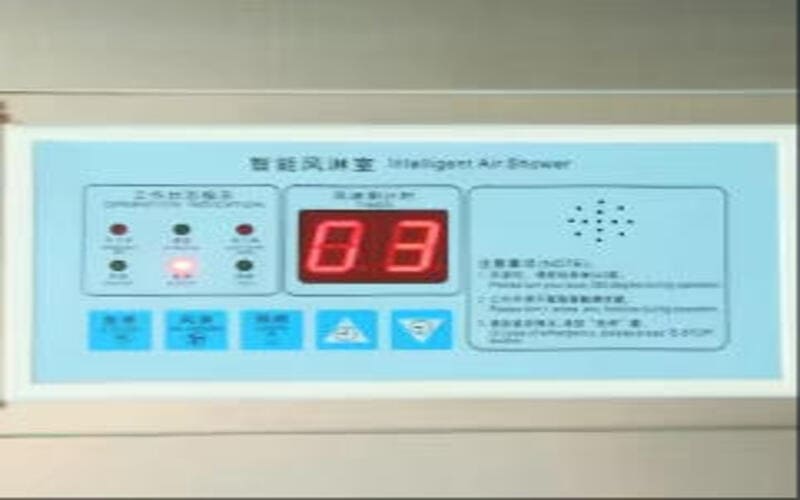

Intelligent operation, voice prompts, real-time display of setting parameters and operating status.

No separators, low resistance, filtration efficiency of 99.99%.

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Lorem ipsum dolor sit amet consectetur adipiscing elit

Stay updated with industry news

Copyright © 2024 Bobencleanroom

Nozzle